What is Product Manufacturing?

Once your product concept is ready, our team transforms it into a detailed 3D model for precise visualization and validation. For cost effective, low volume manufacturing, we utilize advanced 3D printing technologies to rapidly prototype and iterate.

After the engineering design is finalized, we guide you through CMF (Color, Material, Finish) strategies to enhance the product’s aesthetic appeal and market readiness. Our expertise extends to high-volume manufacturing, scaling up production to hundreds of thousands of units, while ensuring design for manufacturability (DFM) and ease of assembly are built into every stage.

Concept Models

The speed and versatility of custom 3d printed items lets product developers create physical snapshots of their designs through the iterative process.

Rapid Prototyping

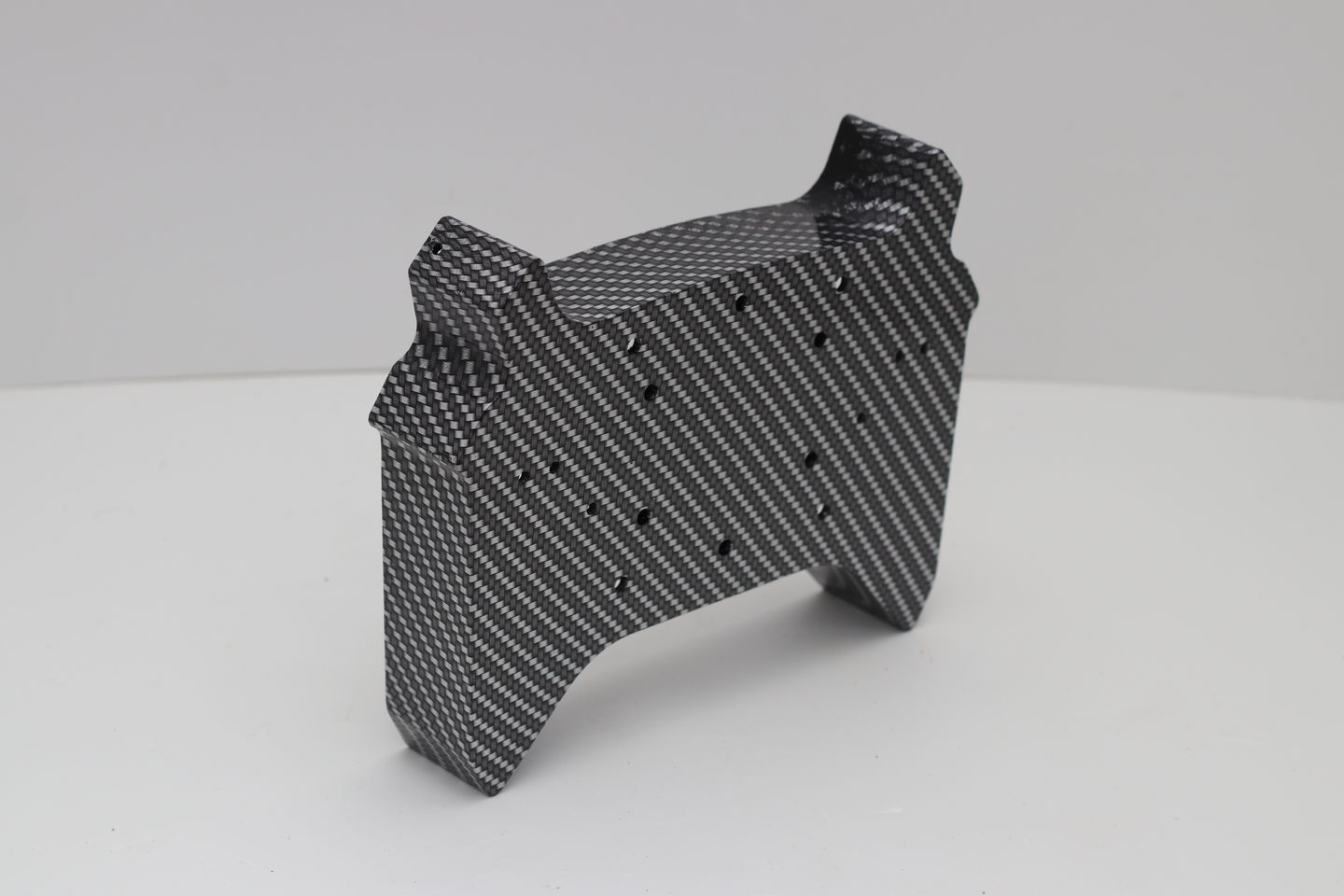

3D Printing can be used to create fully-functional prototypes, complete with moving parts, as well as all-in-one assemblies.

Direct Digital Manufacturing

The high accuracy and consistency of 3D printing makes it an ideal way to build production quantities of discrete or customized parts.

Advantages of 3D Printing

3D printing is a rapidly growing technology with a wide range of potential applications. Some of the key advantages of 3D printing include:

One of the biggest advantages of 3D printing is rapid prototyping. A design can go from a concept to a physical object within a few hours, which is significantly faster than traditional methods.

3D printing can be more cost-effective for small production runs and prototypes. Traditional manufacturing techniques like injection molding have high initial costs, while 3D printing doesn't require any specialized tooling.

3D printing allows for easy design customization without any additional process or cost. Each printed part can be different from the last, which enables a high degree of personalization.

3D printing can create complex shapes and structures that cannot be manufactured with traditional techniques. This includes intricate geometries, internal lattices, or parts with internal components.

3D printing is generally a more sustainable manufacturing process, as it typically has less waste than traditional manufacturing methods. It only uses material that's necessary for creating the part.

Unlike traditional manufacturing methods that often require molds or dies, 3D printing is a tool-less process. This can save a significant amount of time and money, particularly for low-volume manufacturing or prototyping.

Depending on the 3D printing technology used, a wide variety of materials can be used, including plastics, resins, metals, and even ceramics.

Our printing services

We transform your ideas into reality. We are committed to provide a range of services.